OUR PRODUCTS

Flexible Packaging Machine

Vertical Multilane Four Side Seal Packaging Machine

Mohno pump fills liquid product continuously with high weight accuracy, double horizontal seal rollers make reliable seal and MG14 collating machine count.

Stick Packaging Machine with Auger Filler

The machine is servo motor driven which makes product change easy and fast by enabling pre-set of operation condition such as sachet length, filling weight, filling timing, etc.

Single Lane Stick Packaging Machine

This makes it possible to measure and fill various kinds of product on one machine such as powder, granule, liquid, paste, and solid product.

Tablet / Capsule Filling, Sealing, Weigher, Imprinting, and Visual Inspection Machine

Tablet / Capsule Filling Machine

This filling machine enables filling of multiple types of ingredients, including pellets, liquids and powders in the same capsule.

Tablet / Capsule Sealing Machine

The HICAPSEAL 15 is available with 15,000 per hour. This machine can be used for concurrent manufacturing of multiple types of capsules of small quantities.

Weight Inspection Machine

Designed for optimal usage, this MWI inspects the weight of two-piece capsules, softgel capsules and tablets of various shapes and sizes in the same machine.

Imprinting Machine

Innovators in ink jet and laser imprinting technology and provide peace-of-mind that the final dosage formulation is at its best through integrated inspection systems.

Visual Inspection Machine

The CES machine is a fully automatic, high-output visual inspection machine designed to inspect filled capsule products.

Tablet & Capsule Packaging Machine

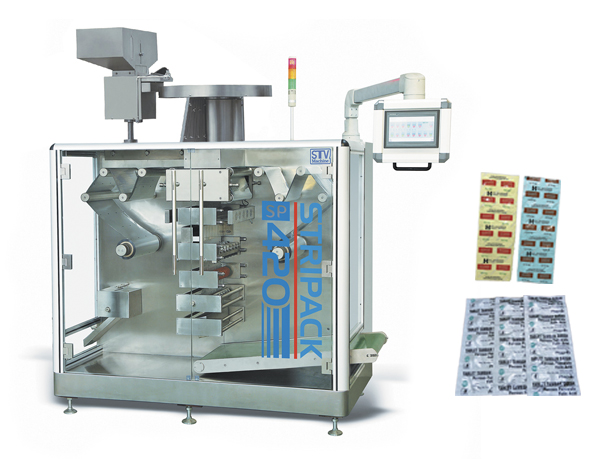

High Speed Automatic Strip Packaging Machine

This machine is suitable for medicine, chemical, food requirement, it can improve product level and is an ideal automatic packaging equipment.

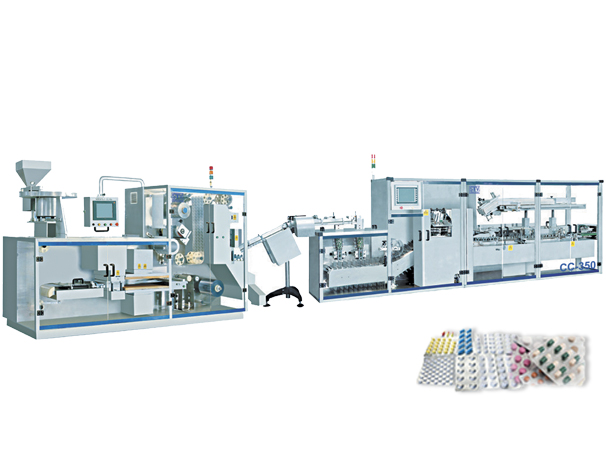

High Speed Blister Packaging Machine and Cartoning Machine

This machine system serve the packaging a cavity or pocket made from a formable web, usually a thermoformed plastic.

Tube Filling Machine

Tube Filling and Closing Machine

Machines for the filling and closure of politene, laminated or aluminium tubes.

Liquid Filling Machine

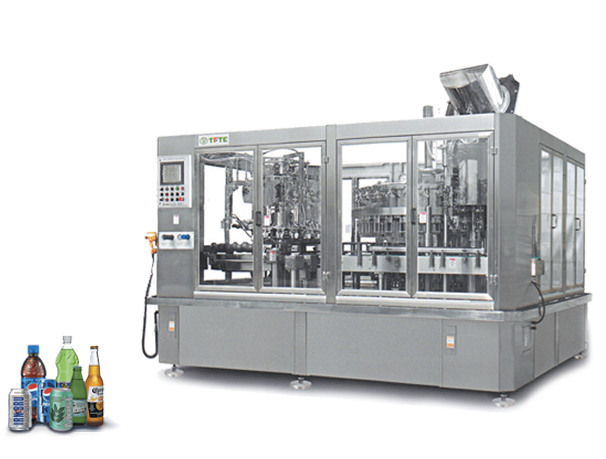

Carbonated Soft Drink Filling

The filler machine has two type bottle and can, the bottle can be glass or plastic, and the suitable beverage is soda water, champagne, beer, carbonated soft drink, and all kinds of carbonated beverages.

Piston Type Volumetric Filling

The feature of the machine is the piston type volumetric filling, it is suitable for filling high viscosity sauce, it adopts non-touch filling, the process of piston is able to change to adjust the filling volume.

Vapor Liquid Separation for Gravity Filling

The filler adopts the gravity filling type and is suitable for filling fresh milk, drinking yogurt, fresh juice (content with fiber) and the temperature sensitivity products.

Filling, Forming of Aluminium foil cap, Induction Type Sealing Machine

The machine is combined with fillers and electrical-heated sealing machines or is combined with induction sealing machines.

.jpg)

Eight Nozzles Auto Filling Machine

FL serials are volumetric filler, it works with various types and shapes of packages and a wide range of liquid material.

Twelve Nozzle Auto Filling Machine with Spiral Pump

Spiral pump filling machine with fast change-over design. Its exceedingly flexible performance is capable of filling think and semi-viscous liquid.

Pouch Filling Packaging Machine

Automatic Fill and Seal Machines for Pre-made Stand-up Pouches

Filling products (Liquid, Paste, Powder, Solid, Lump,.. etc) into preformed plastic pouch and sealing by heat and then discharging fully automatically. Various shaped pouches are available (with zipper/slide zipper, spout).

Horizontal Form Fill Pouch Machine

Availability, performance, and quality. The three pilars for the development of the new SI - 280, designed to maximize overall equipment effectiveness.

Horizontal Form Fill Pouch Machine (Small)

This horizontal pouch packaging machine is available in simplex and duplex versions and can produce up to 180 pouches per minute.

Horizontal Flow Wrapper

Moist Tissue Wrapper for Single Count Package

Fully automatic folding, watering and packaging. Integrated motion sequences from folding, quantitative sprinkling, coding, and wrapping are all fully automatic.

Shrink Packaging Horizontal Flow Wrapper

Shrink film can make your product more attractive, and increase the moisture and dust resistance. Instant bowl noodles, tape, insecticides, aerosol cans, books, CDs, jelly, pudding and other similar products.

Horizontal Flow Wrapper for Biscuit on Edge

Two-step feeding conveyor. Easy to put the product in row. Commonly use in the in-row cookie.

Sleeve & Opp Hot Glue Labeling Machine

Sleeve Labeling Machine

The labeling system can bottle cap, whole bottle(including cap), bottle body, and bottle body fixed position sleeve applications.

OPP/BOPP Labeling Machine

Can apply to round or empty bottle. Labeling: Vertical wrap-around labeling, automatic label cutting, attached to glue and proceed labeling, suitable for hot or cold glue.

Labeling Machine

Wrap-Around Labeler

Manufactured for round container, round containers as well as circular ones (wrap around).

Double Side & Wrap Around Labeler

Manufactured for front and back sides of square, rectangular or oval containers as well as circular ones (wrap around).

Auto Induction Cap Sealer

Induction cap sealing is a non-contact heating process that accomplishes the hermetic sealing of a bottle with a cap which includes a heat-sealable foil liner.

Cartoning Machine

High Speed Automatic Cartoning Machine

Blistering Packaging Machine, combines with Automatic Cartoning Machine to make a complete blister packaging line.

Counting, Grouping, Banding, and Shrink Machine

Automatic Counting, Grouping & Shrink Packaging Machine

Easy to adjust for different sizes packing, simple operation, automatic control, and it can be operated by unexperienced worker to raise production efficiency.

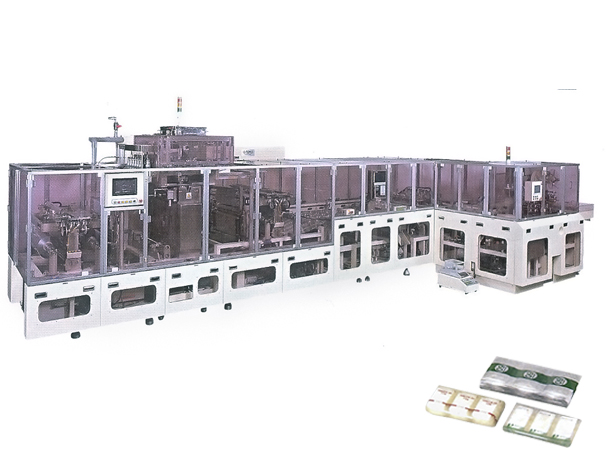

Sachet Packaging, Counting, Collating, and Banding System

Complete packaging system for four side seal sachet packaging, counting, and banding of mainly pharmaceutical granule products.

Case Packer and Pick & Place machine

Case Packer Machine

For the application of confectionery, the model SU-1000 performs the perfect job of box-forming. product accumulating, product inserting, gluing (hot-melt sealing or taping) and closing at high speed.

Pick & Place for Plastic Bottle

To pick-up and place the regular stacking pattern which is formed on the stacking conveyor, it moves up and down, and right and left (X-Y) by servo drive.

Wrap Around and Tray Packaging Machine

Tray Packaging Machine

Human-computer interaction design, semi wrap tray carton packaging operation. The large processing range comprises PVC, PE, PET, PP Bottles, glass bottles, cans and aluminum cans, etc.

Wrap Around Packaging Machine

Human-computer interaction design, fully wrap around carton packing and tray packing operation. The large processing range comprises PVC, PE, PET, PP bottles, glass bottles, cans and aluminum cans, etc.